Deck preparation and construction

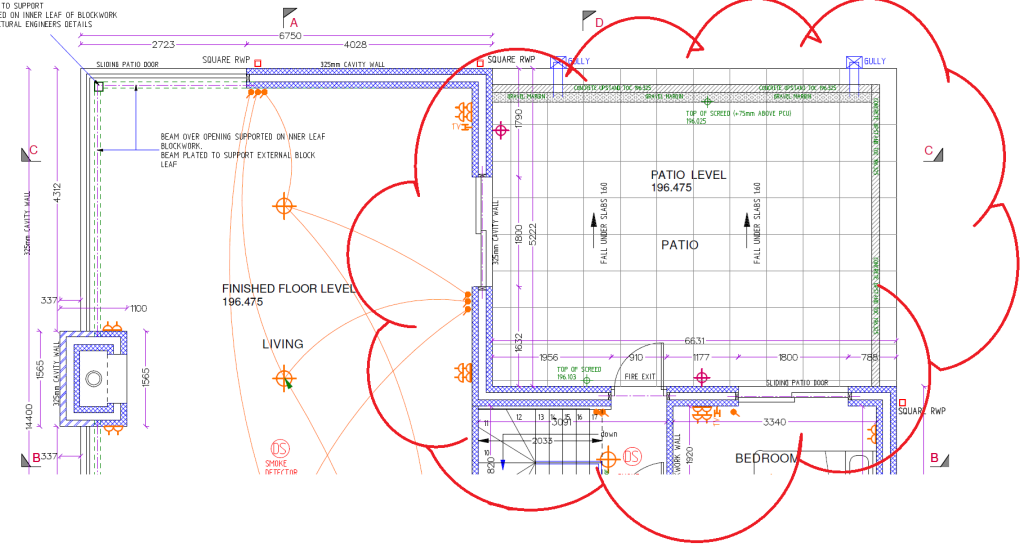

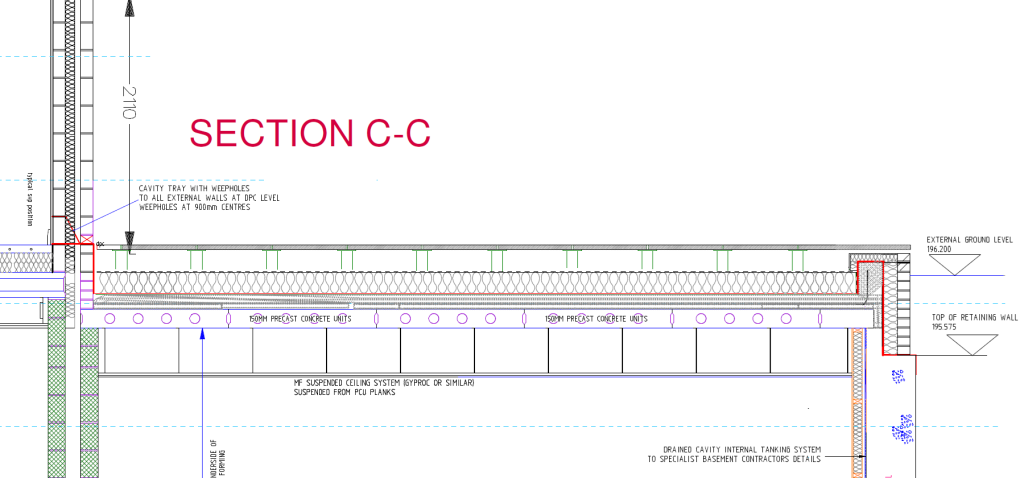

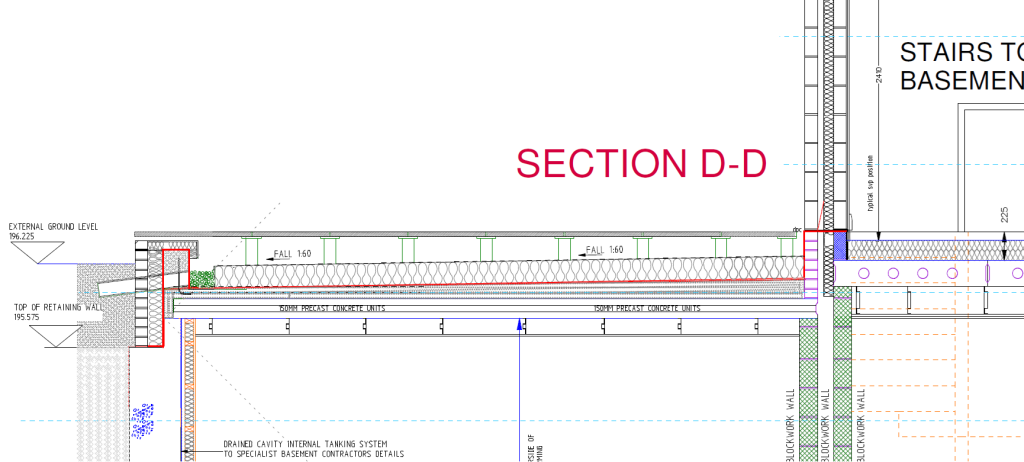

As part of a huge basement complex, the bungalow section has a patio deck above the gym below. Midland Tanking arrived on site with the ground floor slab in place. This floor was created with pre-cast planks, laid on top of the retaining walls below.

Pre-cast plans are laid with small gaps between the to allow for thermal movement, which is necessary but not ideal for waterproofing. Two layers of a 1200 gauge membrane was placed on top of the planks, creating a slip coat. This allows the planks to expand and contract per their design without stressing the layers above.

Reinforcing was laid across the planks and DPM, finally the deck was shuttered and cast with waterproof concrete. The concrete deck has a fall away from the building of 1:60 to ensure no water ever pools. This concrete created a stable and cohesive surface on which to apply the waterproofing.