Cellar waterproofing is an important process as part of a conversion to useable space. This project, in central Birmingham, Midland Tanking was instructed to design and install an appropriate waterproofing system. The overall aim of the project was to enable a full conversion to storage space.

Cellar waterproofing system

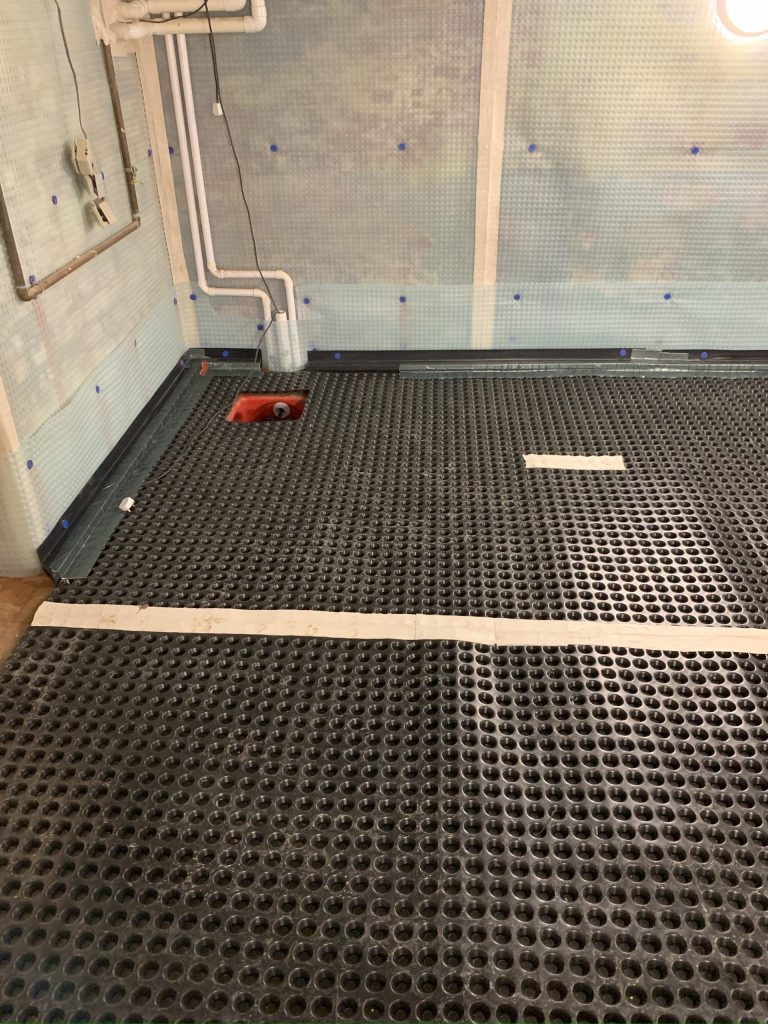

Type C – Drained cavity protection

Midland Tanking designed the cellar waterproofing, taking into account the substrate, age, condition and desired usage for the cellar. The most reliable form of waterproofing for an existing cellar is an internal cavity drainage membrane (CDM) system.

All walls and the floor were lined with a cavity drainage membrane (CDM). These membranes were linked to the sump chamber via perimeter channels. Within the sump are two pumps and a high-level alarm. This system is designed to catch any water, direct it to the sump and discharge it automatically. Flushing and maintenance points were installed to allow future servicing of the system.

The final part of the project for Midland Tanking was covering the floor, thrawl and stairs with timber. This is done to prevent damage being done to the membranes.

Ventilation

A major problem that can occur with cellar waterproofing is damp caused by condensation. This if often wrongly confused with the system being punctured or being ineffectual. The explanation and solution is usually the same.

Having lined the cellar with plastic membranes, relative humidity can be raised to the point where condensation can form. This is often seen on external walls or surfaces. The best way to control this is to install a ventilation system suitable to keep the relative humidity to a consistent level. This prevents condensation forming and eliminates this issue.

The design was conducted by Midland Tanking’s Structural Surveyors in Structural Waterproofing (CSSW) and installation undertaken by qualified technicians in accordance with BS8102:2009

All waterproofing materials were supplied by Triton Systems Ltd