Basement waterproofing on this project was a three part that included a combined-protection system to ensure the transition between the two methods of new build basement.

The basement was built next to an existing building so it was essential the excavation did not collapse. Midland Tanking built the basement using a combination approach. Half of the basement was built using a ground beam and underpin approach, and the other half, a traditional open excavation build. This required a combined approach to the basement waterproofing.

Midland Tanking was the designer and installer for all three systems.

Primary System (Combined Type A & Type B)

Type A – Cementitious slurry Barrier Protection

The ring beam, underpinned walls and floor were all coated with a two coat crystallising waterproofing slurry. This provides this section of the basement waterproofing protection.

Type B – Waterproof concrete integral protection

The traditional build concrete walls were created by erecting temporary shuttering and steel work and then cast with concrete including a waterproof additive. The steel reinforcing within this structure was designed to reduce the cracking to less than 0.3mm, also providing integral protection.

Secondary System

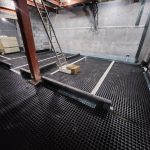

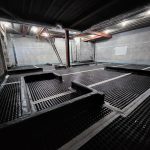

Type C – Drained cavity protection

With the primary waterproof concrete system providing most of the protection, the secondary system was installed. All walls and the floor were lined with a cavity drainage membrane (CDM). These membranes were linked to sump chambers via the a preformed perimeter channel. Within the sump is two pumps and a high-level alarm. This system is designed to catch any water that is not stopped by the primary system and discharge it automatically. Flushing and maintenance points were installed to allow future servicing of the system. The front and rear lower sections are linked with a underground pipe.

Both basement waterproofing systems were designed by Structural Surveyors in Structural Waterproofing (CSSW) in accordance with BS8102:2009

All waterproofing materials were supplied by Triton Systems Ltd