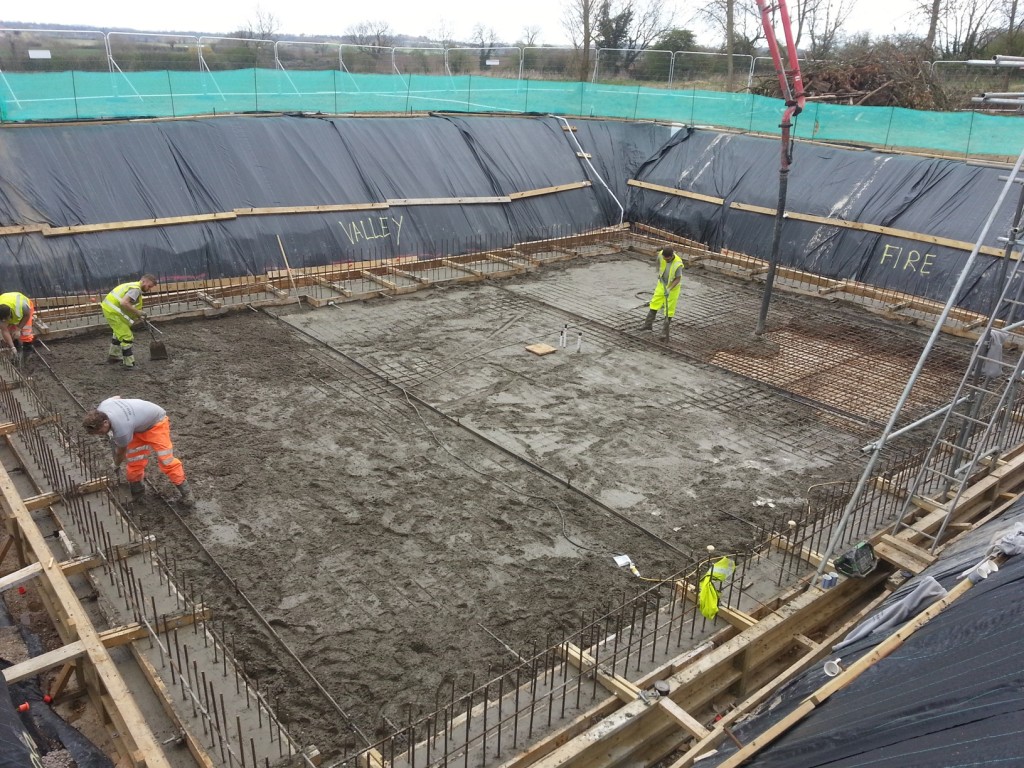

With the site and excavation stable, the basement could begin construction. The first task was to set out where it would sit and install shutters around the perimeter. These shutters were then propped to be level and straight.

Steel reinforcing was built up in layers and bars installed to link the slab to the walls, these “starter bars” were also built in layers.

A ground water sump was cast in the middle and the levels for the slab were formed. Finally, a 150mm upstand known as a “kicker” was built. This kicker forms the first 150mm of the walls and aids in waterproofing. Within the kicker construction a channel was created, allowing an expanding water-stop to be installed later.

The slab was then cast in waterproof concrete and left to cure for three days.

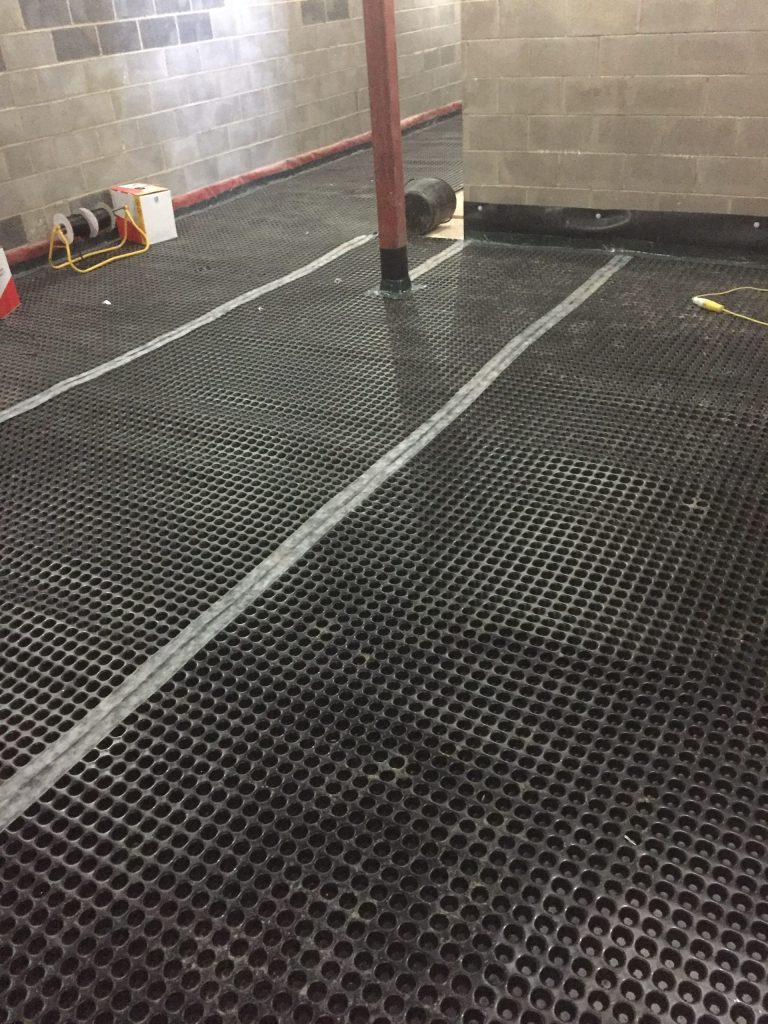

With the slab completed, the walls could be built. As is usual in concrete construction, the walls were built in halves to avoid cracking. Temporary timber shutters were erected externally, the expanding water-stop installed, and steel reinforcing linked to the starter bars.

Once the external shutters and steel were complete, the internal shutters were erected and the everything was braced and strengthened ready for the concrete pour. A temporary scaffold was constructed, and the waterproof concrete was then poured.

With the second half constructed in the same manner, the waterproof concrete basement was complete. Forming a waterproof concrete basement shell. A manhole riser was fit around the external sump and the whole excavation backfilled in layers and compacted. To make ready for the rest of the house build, foundations were joined to the basement walls at the top of the backfill.